This is AEM

To be the most trusted materials supplier to our customers

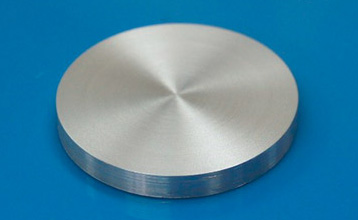

Advanced Engineering Materials Limited (AEM) is an international company involved in the R & D, manufacturing and sales of all kinds of high-tech materials. We provide worldwide research institutes and high-tech enterprises with high purity non-ferrous materials, customized alloys, compounds and almost every kind of complicated synthetic material, etc. We have great advantages in magnetron sputtering targets, vacuum coating materials, high-purity metals, high-purity compounds, rare-earth metals, distilled rare-earth metals, refractory material, coated substrates, nano-powder, high-purity reagents and precision alloys, etc.